Risks in Mining and How to Minimise Them

Listen to article:

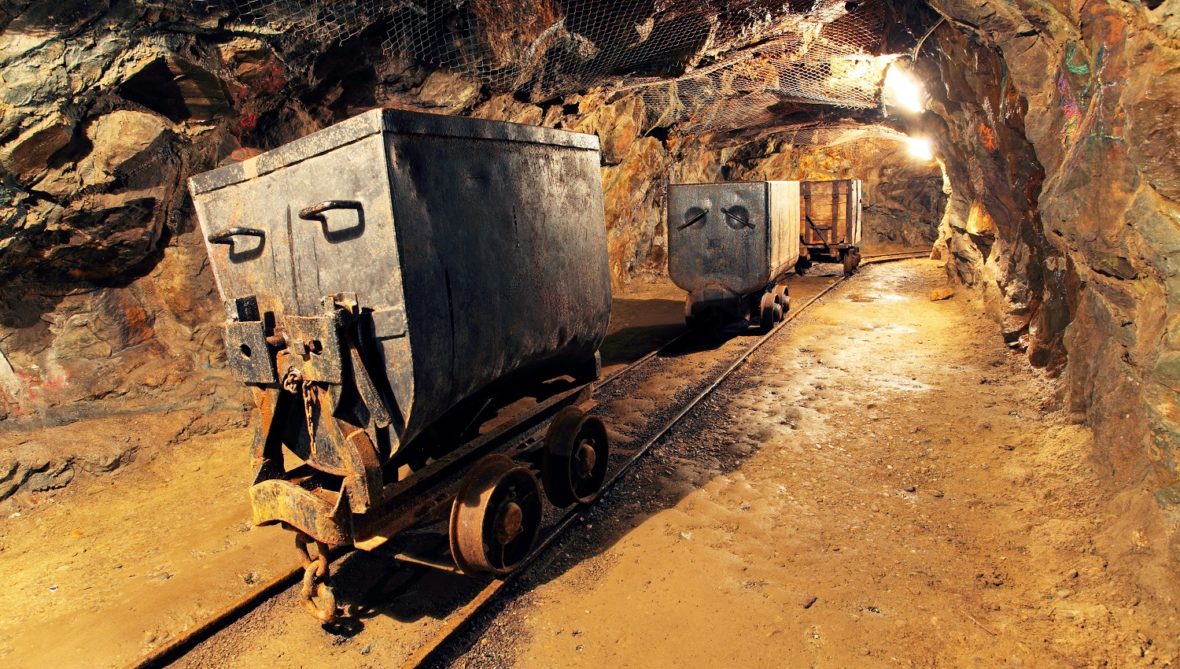

Mining is a crucial part of the progress of our modern civilisation. Raw materials acquired by mining are present in almost all products we base our everyday lives on. That is why the availability of these materials directly influences future technological innovations and the development of many industries. If that is not enough, mining supports our economy by creating jobs where mines are located.

However, such benefits do not come without risks. Throughout the centuries, mining has been regarded as a hazardous profession. There are many causes of accidents, and some of the most common include:

1. Toxic gas leaks

By digging deep into the Earth’s crust, miners often encounter pockets filled with toxic gas that can seriously endanger their health. Hydrogen sulphide is a typical example of such a gas since it has a devastating effect on the nervous system.

2. Explosions

In underground coal mines, an accumulation of methane can form, creating a highly explosive mixture when combined with fine coal particles. Additionally, injuries related to explosions can occur during controlled detonations used for expanding the mining area.

3. Collapsing mine shafts

Collapsing mine shafts can severely threaten miners, whether they happen due to human errors, natural disasters, or seismic activities.

4. Floods

Many mines are created in remote locations, where precipitation and water conditions are not thoroughly studied. The flood risk is also increased because mining constantly changes the surrounding landform.

It is why mine managers must implement many precautionary measures to keep all the above risks under control. Some of the methods used to achieve that are as follows:

1. Safety gear

All miners must wear safety gear to protect them from physical injuries, dangerous chemicals, and hot temperatures. Helmets, protective clothes, boots, and safety goggles are just some equipment miners need to stay safe.

2. Ventilation of harmful gases

Ventilation systems installed in mines can redirect harmful gases outside the mine shaft and, by doing so, provide an acceptable air quality. Sensors for toxic gas detection are essential for managing these systems.

3. Closing mine shafts no longer in use

Mine shafts no longer in use must be sealed shut so they would not decay and collapse over time. Also, abandoned mine shafts can fill up with methane and thus increase the risk of explosion.

4. Security of electrical systems

During excavation, miners use many tools, lighting, and electricity-powered components. These systems must be well-insulated because the moist environment in mines combined with an electrical circuit can cause a tragedy and lead to fatal consequences.

5. Efficient communication

Information about the current working conditions in mines is of crucial importance for miners’ safety. For these purposes, miners use visual signalisation and mobile devices. Clear communication is vital when explosives are used so that all the people at the site are notified to move to a safe distance. The best solution in the case of controlled detonations is sirens, which can warn the people in the surrounding area about any potential danger.

For example, this is how Telegrafia’s sirens, Screamer Car, Bono, or Gibon, can be used. They can be controlled remotely by an operator or another responsible person who can send a clear signal or a voice message and, by doing so, inform everybody in the vicinity about the detonation.

If you are interested in sirens in mines, click on this link or the button below to find answers to your questions.

The article was written by

Vladimir Ilić

Vladimir is a Marketing Assistant responsible for the Balkan countries. Work ethic, problem-solving and attention to detail are attributes he brings to the workplace every day. His proactive personality also translates into physical activity, music and traveling which is how he spends most of his free time.